FOR Volkswagen, the story is not just the cars it makes. With the T-Cross coming to the Philippines soon, it is very interesting to find out how, their assembly plants across the have been silently using ultra-high technology to keep the German precision and craftsmanship at its highest level, and in the case of the pandemic, keep manufacturing going even by working from home.

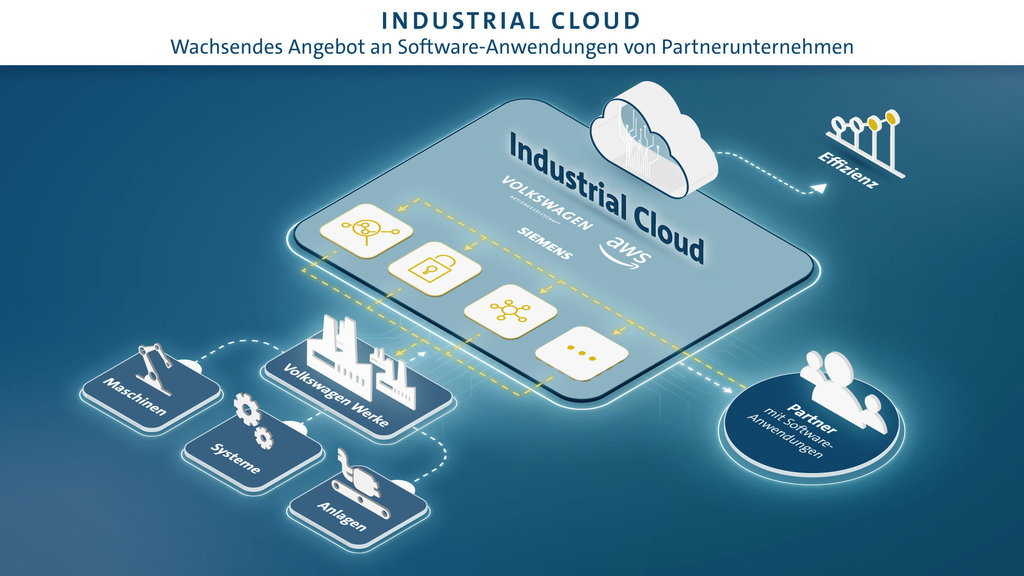

Partnership with AWS and Siemens

This is a tech story, that in the Cloud and involves digital twins. These two tech concepts necessarily mean, Amazon Web Services (AWS) and Siemens.

AWS is the leading provider of Cloud computing services in the world. With its expertise in machine learning, artificial intelligence, built-in applications on its Cloud platform, as well as a massive information security platform humming in place is VW’s perfect partner for its Industrial Cloud.

Siemens is the efficiency expert. As VW’s integration partner, it ensures that production systems, machines and installations of various manufacturers in the global plants are flawless connected to this Cloud project. The basis of the Industrial Cloud is Volkswagen’s Digital Production Platform (DPP), onto which all of the Group’s sites will dock in the future. The platform standardizes and simplifies the exchange of data across systems and plants.

Industrial Cloud to become an app store

By 2025, Volkswagen wants to increase the productivity of its plants by 30 percent compared to 2016.

“We will continue to strengthen production as a competitive factor for the Volkswagen Group,” said Oliver Blume, CEO of Porsche and Member of the Board of Management of Volkswagen AG with responsibility for production. The Industrial Cloud is a crucial lever for achieving this goal. Data from all factories is to be amalgamated and made usable in real-time. Volkswagen is thereby laying the foundations for more efficient processes. In the final stage of expansion, the corporation expects to reduce costs by several billion euros.

Emden plant: Permanent quality control during welding

At the Emden Volkswagen plant, the evaluation of welding data will be used for even better quality control in the future. The challenge: until now, the weld spots on the car bodies have been checked manually using ultrasound. But this takes so much time that the employees tasked with this can only take random samples. “In the future, the welding robots will collect the required data on current flow and voltage automatically. An algorithm checks that the values meet the standards,” said project manager Mathias Boomgaarden. The benefit being that defects will be identified. Members of the present inspection team will monitor the data on the dashboard in future, and perform manual checks in the event of any issues.

Hannover plant: Early warning system in camper van construction

At Volkswagen Nutzfahrzeuge (VWN) in Hannover, an Industrial Cloud app amalgamates data from ongoing production clearly and transparently in one system. This enables users to get a real-time overview of whether potential bottlenecks could occur in production, at just a click of the mouse.

In a pilot project in the production of the T6.1, the standardized evaluation of data already makes vacancies in the buffer sections transparent — a good indicator of potential disruptions in production. “Identifying the buffers with the longest vacancies enables vulnerabilities to be detected and systematically eliminated,” said Hartmut Lí¼dtke, who is leading the project for the production strategy area.

The basic idea for the early warning system originates from the Volkswagen brand’s planning. Therefore, the pilot project was implemented in collaboration with production strategy experts and the Group IT department in Wolfsburg. The team is currently working on creating a scalable solution that can be transferred to other plants with minimal effort. This is due to take place at several sites this year.

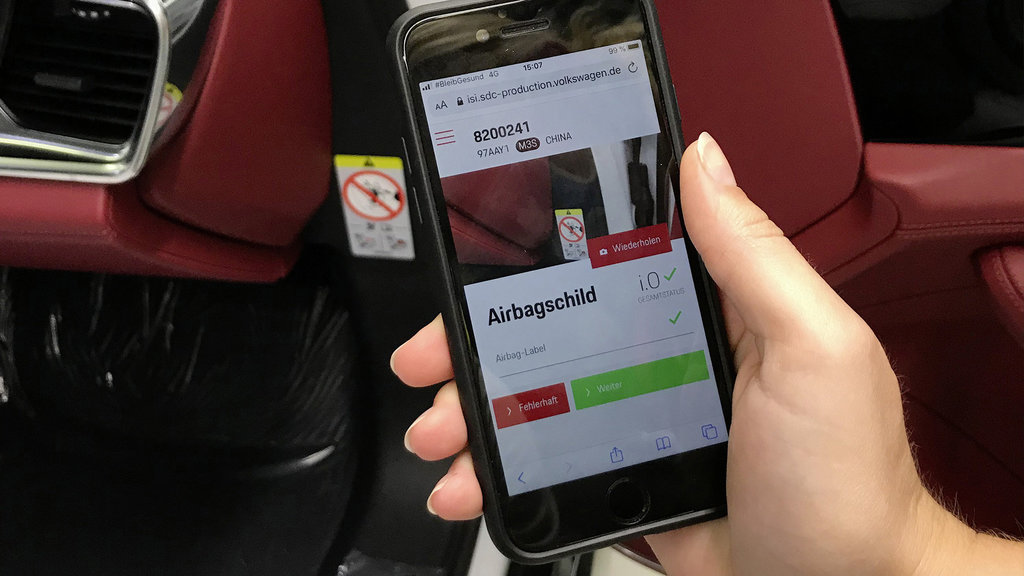

Leipzig plant: Artificial intelligence as a linguistic genius

At Porsche in Saxony, artificial intelligence is proving to be an important aid in monitoring labels in different languages quickly and accurately. The challenge: multiple labels with vehicle information or tips for airbags are affixed to every vehicle manufactured. Many of these stickers contain country-specific information and are written in the customer’s language. At the Porsche plant in Leipzig, an app uses photos to compare the content of the labels in real-time and provides feedback on whether everything is ok. This saves several minutes per vehicle.

However, the Industrial Cloud is not restricted to the Volkswagen Group’s sites; it goes far beyond that in perspective: in 2020, the corporation opened the cloud up to partners from engineering and technology, who provide their own software solutions. For example, one of these corporations developed an algorithm that uses AI to optimise the use of driverless transportation systems. The application of another corporation enables the simulation of the maintenance intervals of machines. As the number of partners grows, so does the range of solutions, to which the sites have access.